A Subterrene (Latin: Subterrina) (Russian: Подземная лодка) is a vehicle that travels underground (through solid rock/soil) much as a submarine travels underwater, either by mechanical drilling, or by melting its way forward. Subterrenes existed first in fiction as mechanical drillers, with real-world thermal designs and examples following in the second half of the 20th century.

Fictional subterrenes are often depicted as cylindrical in shape with conical drill heads at one or both ends, sometimes with some kind of tank-tread for propulsion, and described either as leaving an empty tunnel behind it, or as filling the space behind it with mining debris. The plausibility of such machines has declined with the advent of the real-world tunnel boring machines, which demonstrate the reality of the boring task. Tunnel boring machine themselves are not usually considered to be subterrenes, possibly because they lack the secondary attributes – mobility and independence – that are normally applied to vehicles.

A real-world, mobile subterrene must work thermally, using very high temperature and immense pressure to melt and push through rock. The front of the machine is equipped with a stationary drill tip which is kept at 1,300–1,700 °F (700–930 °C). The molten rock is pushed around the edges as the vehicle is forced forward, and cools to a glass-like lining of the tunnel. Massive amounts of energy are required to heat the drill head, supplied via nuclear power or electricity. Patents issued in the 1970s[1] indicate that U.S. scientists had planned to use nuclear power to liquefy lithium metal and circulate it to the front of the machine (drill). An onboard nuclear reactor can permit a truly independent subterrene, but cooling the reactor is a difficult problem. The Soviet Union is purported to have built such a “battle mole”, which operated until its onboard reactor failed.

On line information presents research was funded by the United States Government for the Los Alamos Scientific Laboratories University of California, Los Alamos, New Mexico for a project Camelot under the heading Systems and Cost Analysis for a Nuclear Subterrene Tunneling Machine. A patent was subsequently issued under number 3,693,731 on September 26, 1972. A patent search can be made with full text and images at www.uspto.gov.

The design concepts fall into similar designs of current technology of our nuclear submarine fleet and existing tunnel boring technology as used in the Chunnel between England and France, but with the added feature of melting rock for the tunnel wall lining.

Source https://en.wikipedia.org/wiki/Subterrene

LA TIMES, JUNE 11, 1972

BEGIN ARTICLE QUOTE”

“L.A. to N.Y. in Half an Hour?

10,000 – M.P.H. Tunnel Train Plan Developed

By: Times Science Writer – George Getz

A Rand corporation physicist has devised a rapid transit system to get you from Los Angeles to NY in half an hour for a $50 fair. He said existing technology made such a system feasible and so does a cost analysis. The essence of the idea is to dig a tunnel more or less along the present routes of U.S. highways 66 and thirty. The tunnel would contain several large tubes for East West travel of trains that float on magnetic fields, moving at top speeds of 10,000 mph. Passengers would faced forwarded during acceleration, backward during deceleration. According to R. M. Salter Jr. head of the physical sciences department at Rand, the idea of high-speed train travel using electromagnetic suspension was first put forward in 1905 and actually patented in 1912. The trains he suggested now would be single cars rather than actual trains, and would be big enough to carry both passengers and freight, including large containers and automobiles.

Could Carry Automobiles

The cars, or gondolas, would leave the New York and Los Angeles terminals at one minute or even 30 second intervals. On the main line their would be intermediate stops at Amarillo and Chicago. Feeder lines would meet the main lines at both locations. Their would also be subsidiary lines coming into the two main terminals from such cities as San Francisco, Boston and Washington. The main idea of VHST, or Very High Speed Transit, developed originally in thinking about the satellite program and hyper sonic aircraft speeds.” Salter said in an interview at Rand. “The underground tubes were for suggested as alternatives, perhaps not quite seriously, but it was soon apparent that the idea of a tunnel containing such tubes had a lot of real advantages.” he said.

Conservation of Energy

In the first place, he explained there is the extremely important matter of the use and conservation of immense amounts of energy needed to move the vehicles at such great speed. “An airplane that travels faster than sound uses up a large part of its available energy supply just in climbing to an altitude where the speeds for which it is designed are possible.” Salter said. “That’s true of rockets to. Much of their energy is spent and lost forever and getting above the atmosphere.” This would not be true for the VHST gondolas traveling on their electromagnetic rail beds, according to Salter. The tubes would be emptied of air, almost to the point of vacuum, so the trains would not need much power to overcome air resistance. They would not even have to be streamlined. In addition to an electromagnetic roadbeds, the opposing electromagnetic loops of wires in the floors of the gondolas would be super cooled with liquid Helium to further eliminate electrical resistance.

Breaking Generates Power

Just as important, the gondolas would, like old-fashioned trolley cars, generate power as they break to a stop. “Since the trains would be leaving New York and Los Angeles simultaneously every minute, the power generated by cars breaking coming into the terminal would be transferred to the power lines propelling the cars going the other way.” “For example, there will be halfway points between each stop. Trains would use power and getting to that halfway point, and generate power going the other half of the way to the stop. Each would use power generated by trains going in the other direction.” That is the way trolley cars have operated for eighty years – taking power from the overhead lines while accelerating or running along at a steady speed, and putting power back into the lines while breaking or coasting. The big drawback to the Salter scheme is the cost of tunneling across the nation. He admitted that it would be expensive but it does not daunt him. “After the tunneling was finished, everything else would be practically free.” He said. Even at the low fair he proposes, the enormous debt created by the tunneling would be amortized within a reasonable period if the number of passengers and the amount of freight came up to Salter’s expectations. He figures the tunnel’s would carry seven or 8 million tons of freight a day and that passengers would take to traveling back and forth between the Eastern West Coast has readily as they now fly between San Francisco and Los Angeles. “The technology of this is much easier than was developed for the space program.”

Salter said. And tunnels, he added, need not be so expensive to dig is people think. The most expensive thing about surface routes is the acquiring right-of-way and removing buildings that stand on the chosen route. The tunnel would not incur this expense. The tunnel, besides carrying tubes for passenger and freight gondolas, would carry many of the utilities now strung across the countryside on high wires. Salter said these underground power “lines” could be super-cooled with helium, like the electromagnetic loops in the floors of the gondolas. He said this would so reduce resistance that power could be transferred from one end of the country to the other without appreciable loss. At the present time long distance transportation of power is difficult because of the amount of energy wasted. He said laser beams could be carried in the tunnel for the instantaneous transmission of messages. Even the mail could go cross-country in pneumatic tubes carried in the tunnel. All this would save money and speed amortization, thus cutting the overall cost of tunneling. Salter said approximately 8000 miles of tunnel were dug in America and Western Europe in the 1960s. That includes mine shafts. But he said existing tunneling technology could be vastly improved. Salter said many tunnels are dug nowadays almost as they would have been in the dark ages. Drilling holes in tunnel faces, and using machines with rotary bits are methods of tunneling that can be improved, according to him. He said the tunnel could be worked on from a great many “faces,” for instance. Salter suggested, too, that electronic beams or even water be used to drill holes for blasting. The high-powered electrons would drill blasting holes almost instantaneously.

Travel by Airplane

Projections of future airplane and automobile travels in the United States, and the future train and truck transfer of freight, show that Salter’s tunnel idea is not a science fiction fantasy. There will be more room in the tunnels for all the necessary transport than there will be over any feasible number of Airways and freeways and tracks. Salter’s suggestion, according to the experts who have had a look at it, is an eminently practical one for handling all the necessary traffic cleanly and without clogging up the air and surface pathways. But it will such a system ever be developed? Salter himself is not optimistic. “Perhaps” is how he puts it. “I am not nearly so optimistic about the political aspects of the problem as I am about our technical capability of doing the job.” He said. “History shows that some obviously feasible and practical projects, such as the tunnel proposed over and over again for connecting England and France under the English channel, can be put off for centuries because of political pressure. On the other hand, societies with relatively primitive technology can perform such engineering feats as the erection of impairments.” Is the VHS T too far out? Salter suggested that to get the right perspective we should look back 100 years.

Comparison Made

By comparing transportation a century ago and transportation today, one gets a better feel for just how practical VHST is. It appears to be a logical next step, and much more practical than its alternatives of filling the highways and Airways with more and more individually guided vehicles. “This alone is a compelling reason for the high-speed system.” Salter said. There are others, according to him. “We can’t afford any longer to continue indefinitely to pollute the skies with heat, chemicals, not to mention noise, or to carve up the land with pavement.” He said. “We also need to get the trucks and many of the cars off the highway to make the roads available to drivers who drive the family car for fun and convenience.”

Source

Rand Corporation Documents Supported Creation

of a 14.000 MPH U.S. Tube Shuttle Network

by John Rhodes

Excerpt

SOURCE

Government whistleblowers and retired military personnel have publicly stated that during their employment they observed that our government has a massive network of tunnels, with super velocity trains, linking secret underground bases. (Thomas Castello, the former Dulce Base security officer, reported to an associate that Dulce had a tube-shuttle station linked to several other secret underground bases.)

At first hearing, these statements seem too far-out to be true. We’ve all seen television shows about tunnels and they always show how expensive, dangerous, and disastrous near-surface tunnel construction can be. So, obviously an undertaking such as constructing a massive, sci-fi-like network of underground tunnels would take too much money and hundreds of years to build! NOT SO, say scientists!

In 1972, Robert M. Salter, lead scientist with the Rand Corporation, announced during an interview with LA Times science writer George Getz, that a high speed system could be built using existing (1972) technologies. He also stated that the system should be built for environmental and economic reasons. What kind of speeds was he talking about? Try 10,000 MPH! (Read this June 11, 1972 LA Times article).

On August 2nd, 1972, Salter wrote Rand document P-4874. The publication was titled, “The Very High Speed Transit [VHST] System.” The 17-page report detailed the technologies involved, possible attained speeds, aspects of economic and security benefits, and potential routes. This document reported achievable passenger speeds at 14,000 MPH!

Overview of documents and links to download the declassified archives.

File 1 file 2 file 3 file 4 file 5 file 6 file 7 file 8 file 9

Apparatus and method for large tunnel excavation in soft and incompetent rock or ground

A tunneling machine for producing large tunnels in soft rock or wet, clayey, unconsolidated or bouldery earth by simultaneously detaching the tunnel core by thermal melting a boundary kerf into the tunnel face and forming a supporting excavation wall liner by deflecting the molten materials against the excavation walls to provide, when solidified, a continuous wall supporting liner, and detaching the tunnel face circumscribed by the kerf with powered mechanical earth detachment means and in which the heat required for melting the kerf and liner material is provided by a compact nuclear reactor.

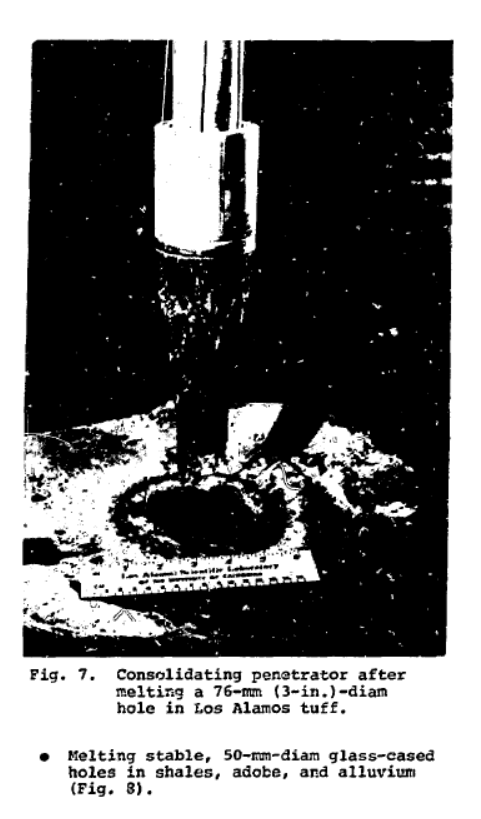

Design concepts and preliminary specifications are described fcr a Subterrene system that forms small-diameter horizontal holes in rock by melting and simultaneously lines the hole with glassy rock melt. Most components of the system are commercially available. Deviation sensors and alignment-control units car be added to ensure that the holes are straight. The design and operation of this Subterrene system are described and proposed development approaches for the hole-forming assembly are discussed.

I. INTRODUCTION

A. Program History

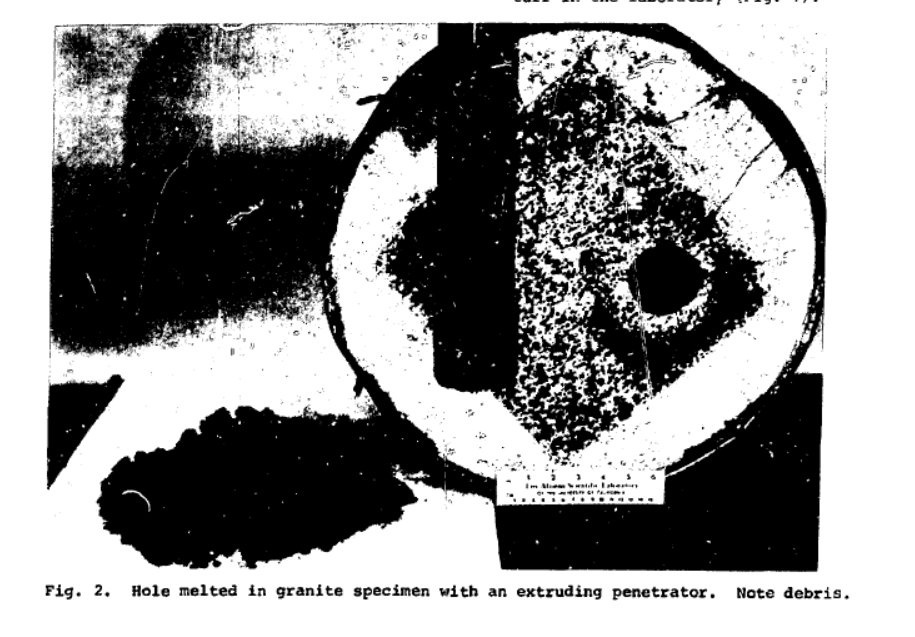

Rock-melting penetrators (Subterrenes) are under development at the Los Alamos Scientific Laboratory (LASL) to produce self* supporting glass-lined holes in rock and soil (Fig. 1) by progressive melting rather than by chipping, abrading, or spalling.1 Recks and soils melt at temperatures that are relatively high: contnon igneous rocks at ‘v 1500 K, almost at the melting temperature of steel (1500 to 1800 K). Thus, the molting penetrators must utilize refractory metals such as molybdenum (Mo) and tungsten (W), which melt at 2880 and 3650 K, respectively, and which, in addition, have low creep rates at the rock-melting temperatures.

Excavation by rock- and soil-melting offers potentially new and novel solutions to the three major areas of the excavation process:

• Making the hole or breaking up the rock.

• Providing structural support for the bore hole.

• Removing or displacing the debris or cuttings.

The liquid form of the rock- and soil-melt produced by a heated penetrator introduces new solution concepts into the latter two areas:

• The liquid melt can be formed into a glass lining to seal or support the walls of the bore hole, and

• Any excess liquid melt can be chilled and formed into glass rods, glass pellets, or rock wool (Figs. 2 and 3); or used to form a glass-cased core that can be removed by present wire-line methods.

The liquid melt produced by soil- and rock-melting techniques offers the potential

of a complete systems approach to the processes of hole making, tunneling, and excavation. The LASL development program in rock- and soil-melting techniques has already demonstrated in laboratory and field tests an attractive advancement in practical excavation technology for the production of short, horizontal, small-diameter holes.

This experience has been partially developed

through the extensive testing of melting-consolidating penetrators (MCPs). The tests consisted of:

• Melting 50-mm (2-in.)-diam, glass-lined drain holes in Indian ruins3

at Bandelier National Monument (Fig. 4).

• Melting a 50-mm (2-in.)-diam glass-lined vertical hole in Los Alamos vclcanic tuff to a depth of 26 n.

(82 ft) in a single run.

• Melting a 50-mm (2-in.)-diam glass-lined horizontal hole in Los Alamos volcanic tuff to a length of 16 m (50 ft) (Figs. 5 and 6).

• Melting a sequence of 76-mm (3-in.)-diam glass-lined holes in volcanic tuff in the laboratory (Fig. 7).

Method and Apparatus for Tunneling by Melting

Publication number: US3693731

Publication date: 1972-09-26

Inventor: ARMSTRONG DALE E; MCINTEER BERTHUS B; MILLS ROBERT L; POTTER ROBERT M; ROBINSON EUGENE S; ROWLEY JOHN C; SMITH MORTON C

Applicant: ATOMIC ENERGY COMMISSION

Abstract of US3693731

A machine and method for drilling bore holes and tunnels by melting in which a housing is provided for supporting a heat source and a heated end portion and in which the necessary melting heat is delivered to the walls of the end portion at a rate sufficient to melt rock and during operation of which the molten material may be disposed adjacent the boring zone in cracks in the rock and as a vitreous wall lining of the tunnel so formed. The heat source can be electrical or nuclear but for deep drilling is preferably a nuclear reactor.

Apparatus and Method for Large Tunnel Excavation in Hard Rock

Publication number: US3885832

Publication date: 1975-05-27

Inventor: ALTSEIMER JOHN H; HANOLD ROBERT J

Applicant: US ENERGY

Abstract of US3885832

A tunneling machine for producing large tunnels in rock by progressive detachment of the tunnel core by thermal melting a boundary kerf into the tunnel face and simultaneously forming an initial tunnel wall support by deflecting the molten materials against the tunnel walls to provide, when solidified, a continuous liner; and fragmenting the tunnel core circumscribed by the kerf by thermal stress fracturing and in which the heat required for such operations is supplied by a compact nuclear reactor.

Apparatus and Method for Large Tunnel Excavation in Soft & Incompetent Rock or Ground

Publication number: US3881777

Publication date: 1975-05-06

Inventor: ALTSEIMER JOHN H; HANOLD ROBERT J

Applicant: US ENERGY

Abstract of US3881777

A tunneling machine for producing large tunnels in soft rock or wet, clayey, unconsolidated or bouldery earth by simultaneously detaching the tunnel core by thermal melting a boundary kerf into the tunnel face and forming a supporting excavation wall liner by deflecting the molten materials against the excavation walls to provide, when solidified, a continuous wall supporting liner, and detaching the tunnel face circumscribed by the kerf with powered mechanical earth detachment means and in which the heat required for melting the kerf and liner material is provided by a compact nuclear reactor.

Extreme Engineering Transatlantic Tunnel

A proposed high speed Mag-lev travelling in a submerged vacuum tunnel, spanning the continents of the Americas and Europe.

Zorgon drew my attention to the fact that the main elements of the project (less the submerged element)have been kicked around for near on 40 years .

Комментариев нет:

Отправить комментарий